1-Hour Fire Rating refers to a standardized fire resistance classification indicating that a building assembly, material, or component can withstand exposure to fire conditions for a minimum of one hour while maintaining its structural integrity and preventing flame penetration. This rating is determined through rigorous testing procedures established by organizations such as Underwriters Laboratories (UL) and ASTM International, where assemblies are subjected to controlled fire exposure following specific time-temperature curves. The 1-hour fire rating is one of the most commonly specified fire resistance requirements in commercial and residential construction, serving as a critical safety measure for occupant protection and property preservation.

1-Hour Fire Rating

|

|

|---|---|

| Category | Fire Safety, Building Codes |

| Subfield | Fire Protection, Structural Systems |

| Key Characteristics | 60-minute resistance, structural integrity, flame barrier |

| Primary Applications | Walls, floors, ceilings, doors, structural members |

| Industry Impact | Life safety, code compliance, insurance requirements |

| Sources: IBC, NFPA 101, UL Standards, ASTM E119 | |

Other Names

One-hour fire resistance rating, 60-minute fire rating, 1-hour fire assembly, Class A fire rating, F60 rating, REI 60, fire-rated assembly

History

1900s-1910s: Early Fire Testing Development

The devastating urban fires of the early 1900s, including the 1906 San Francisco earthquake fires and 1911 Triangle Shirtwaist Factory fire, catalyzed the development of standardized fire testing. Early efforts focused on understanding how long building materials could withstand fire exposure before structural failure occurred. The National Board of Fire Underwriters began developing the first systematic approaches to fire resistance testing.

1920s-1930s: Standard Time-Temperature Curves

ASTM developed the foundational E119 standard during this period, establishing the standard fire curve that remains in use today. The test reaches 1,000°F within 5 minutes, 1,700°F at 1 hour, and 2,000°F at 4 hours. This standardization allowed for consistent comparison of fire-resistant assemblies across manufacturers and regions, with the 1-hour benchmark emerging as a practical minimum for many building applications.

1940s-1950s: Post-War Construction Standards

World War II accelerated materials science development, leading to improved fire-resistant assemblies. The establishment of Underwriters Laboratories as the primary testing authority standardized the certification process. The 1-hour fire rating became codified in building regulations as urban density increased and high-rise construction expanded, requiring reliable fire separation between occupancies.

1960s-1970s: Modern Building Code Integration

The development of modern building codes integrated 1-hour fire ratings into comprehensive fire safety strategies. The National Fire Protection Association expanded NFPA 101 Life Safety Code to include detailed fire resistance requirements. This period saw the introduction of fire-rated door and window assemblies, with manufacturers developing complete systems rather than individual components.

1980s-1990s: Advanced Materials and Systems

Introduction of lightweight steel framing and engineered lumber products required new approaches to achieving 1-hour fire ratings. Spray-applied fireproofing, intumescent coatings, and gypsum-based assemblies became standard solutions. Computer modeling began supplementing physical testing, allowing for more efficient assembly design and optimization.

2000s-2010s: Performance-Based Design

Building codes evolved to include performance-based fire protection design, allowing engineers to use advanced fire modeling software to demonstrate equivalent safety levels. This period saw increased use of fire-rated glazing systems and the development of more efficient fire-resistant assemblies using advanced materials and manufacturing techniques.

2020s-Present: Sustainable Fire Protection

Current developments focus on environmentally sustainable fire protection materials and systems that maintain 1-hour fire ratings while reducing environmental impact. Advanced testing methods now include smoke production and toxicity evaluation alongside traditional fire resistance testing. Digital documentation and traceability systems ensure proper installation and maintenance of fire-rated assemblies.

Technical Specifications

Testing Standards and Criteria

The 1-hour fire rating is established through ASTM E119 or UL 263 testing procedures, where assemblies are exposed to a standard time-temperature curve reaching 1,000°F at 5 minutes, 1,550°F at 30 minutes, and 1,700°F at 60 minutes. Test specimens must maintain structural integrity under maximum design loads while preventing flame penetration and limiting temperature rise on the unexposed surface to 325°F above ambient temperature.

Performance Requirements

Fire-rated assemblies must meet three critical criteria: structural adequacy (load-bearing capacity maintained), integrity (no through-openings or flame penetration), and insulation (temperature rise limitation). Test specimens typically measure 8×12 feet for walls and 12×16 feet for floor assemblies, representing full-scale construction conditions with realistic loading and restraint conditions.

Applications

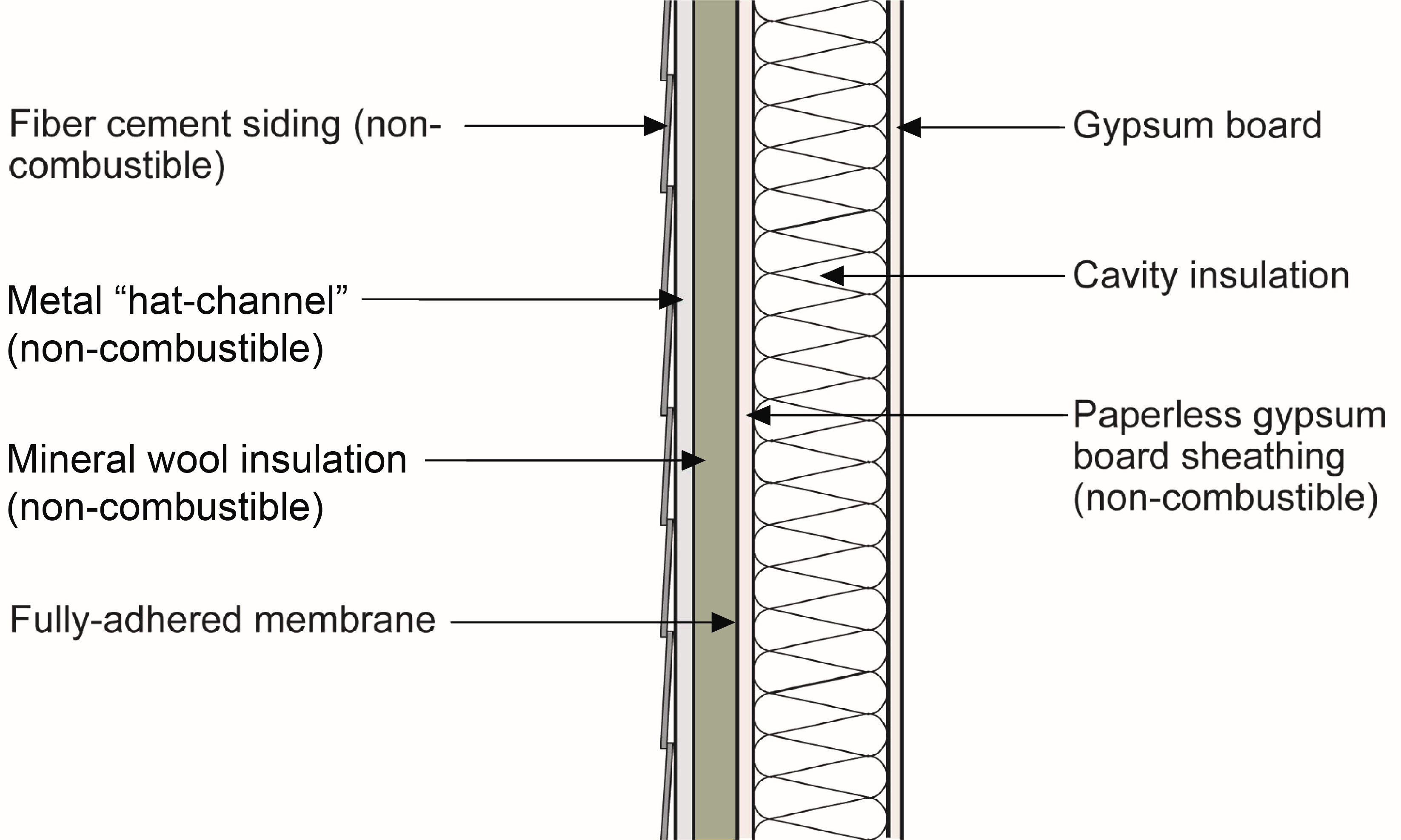

Structural Fire Protection

Steel beams and columns commonly require 1-hour fire protection in mid-rise construction, achieved through spray-applied fireproofing materials, intumescent coatings, or encasement in gypsum board assemblies. Concrete structural members typically achieve 1-hour ratings through proper concrete cover over reinforcing steel, with minimum cover depths specified based on aggregate type and concrete density.

Separating Construction

Fire separation walls, floor-ceiling assemblies, and roof-ceiling assemblies frequently require 1-hour ratings to compartmentalize buildings and prevent fire spread between occupancies. These assemblies include apartment separations in residential construction, tenant separations in commercial buildings, and exit corridor walls throughout various building types requiring protected egress paths.

Best Practices

Design Considerations

Successful 1-hour fire-rated assemblies require careful attention to detail design, including proper firestopping at penetrations, appropriate fastener selection and spacing, and consideration of differential thermal expansion. Design professionals should specify tested assemblies from recognized testing laboratories rather than attempting to interpolate between different configurations.

Installation Requirements

Fire-rated assemblies must be installed exactly as tested and listed, with no field modifications permitted without engineering evaluation. Proper installation includes maintaining specified fastener patterns, joint details, and material thicknesses. Third-party special inspection is typically required during construction to verify compliance with tested configurations.

Industry Standards

Testing and Certification

UL 263 and ASTM E119 provide the primary testing standards for fire-rated assemblies in the United States, while international standards include ISO 834 and EN 1363. Testing laboratories must be accredited by recognized bodies such as NVLAP or A2LA. Manufacturers must maintain quality control programs and conduct periodic retesting to maintain listings.

Code Requirements

International Building Code (IBC) and NFPA 101 Life Safety Code specify where 1-hour fire ratings are required based on occupancy type, building height, and construction type. Local jurisdictions may have additional requirements or modifications to model codes. Installation must comply with manufacturer’s published installation instructions and applicable building code provisions.

Key Considerations

Planning Phase

Design teams must identify all locations requiring 1-hour fire ratings early in the design process, including structural members, separating walls, floor-ceiling assemblies, and opening protectives. Fire rating requirements affect architectural layouts, structural systems selection, and mechanical/electrical system routing. Coordination between disciplines is essential to avoid conflicts between fire-rated assemblies and building systems.

Implementation

Construction sequencing must account for fire protection application timing, particularly for spray-applied fireproofing that requires clean substrate surfaces and specific environmental conditions. Temporary fire protection may be required during construction phases. Quality control measures include material delivery verification, environmental condition monitoring during application, and thickness measurements for spray-applied materials.

Quality Control

Special inspection requirements typically include verification of assembly components, fastener patterns, joint details, and overall compliance with tested configurations. Thickness measurements are required for spray-applied fireproofing using calibrated gauges at specified intervals. Penetration firestopping systems require inspection before concealment to verify proper installation and materials.

Safety Requirements

Installation of fire protection materials often involves elevated work platforms, spray equipment, and potentially hazardous materials requiring appropriate personal protective equipment and ventilation systems. Material safety data sheets must be reviewed for health and safety requirements. Hot work permits may be required for certain installation procedures.

Maintenance

Fire-rated assemblies require periodic inspection to identify damage, alterations, or deterioration that could compromise fire resistance. Spray-applied fireproofing should be inspected for adhesion, cracking, or mechanical damage. Any modifications to fire-rated assemblies require evaluation by qualified fire protection engineers to ensure continued compliance with rating requirements.

Common Issues

Improper penetration sealing is the most common cause of fire rating compromise, often resulting from inadequate firestopping materials or incorrect installation procedures. Field modifications to tested assemblies without proper engineering evaluation can void fire ratings. Inadequate protection of fireproofing materials during construction can result in damage requiring repair or replacement before occupancy.

Project Impact

Cost and Schedule Implications

Fire-rated assemblies typically add 15-25% to the cost of basic construction assemblies, depending on the specific system and application. Schedule impacts include material procurement lead times, specialized contractor coordination, and required inspection hold points. Early identification and specification of fire rating requirements prevents costly design changes and construction delays.

Design Flexibility

Understanding available fire-rated assembly options allows architects to optimize building layouts while meeting code requirements. Modern fire-rated systems offer increased flexibility in architectural expression while maintaining required fire resistance performance. Proper planning can minimize the impact of fire rating requirements on building aesthetics and functionality.

Industry Impact

Safety and Regulatory Evolution

The widespread adoption of 1-hour fire ratings has significantly improved building fire safety performance and reduced property losses from structural fire damage. Building code evolution continues to refine fire rating requirements based on fire research and real-world fire performance data. Insurance industry recognition of fire-rated construction often results in reduced premiums for building owners.

Innovation and Technology

Fire protection industry innovation continues to develop more efficient and sustainable materials and systems for achieving 1-hour fire ratings. Advanced materials science has produced lighter, more effective fire protection products with reduced environmental impact. Digital technologies enable better quality control and documentation of fire-rated assembly installation and maintenance.

Current Debates

Performance-Based Design Integration

Building code officials and fire protection engineers are increasingly debating the appropriate balance between prescriptive fire rating requirements and performance-based design approaches that use computer fire modeling to demonstrate equivalent safety levels. Some jurisdictions are adopting more flexible approaches that allow alternative compliance paths when supported by rigorous engineering analysis and peer review processes.

Sustainability and Environmental Impact

The construction industry is grappling with environmental concerns related to traditional fire protection materials, particularly spray-applied fireproofing containing synthetic materials. Research into bio-based and recycled content fire protection materials is advancing, though questions remain about long-term durability and fire performance compared to established systems.

Related Technologies

Fire Detection and Suppression Integration

Modern fire-rated assemblies are increasingly designed to work in conjunction with active fire protection systems including sprinklers, smoke detection, and fire alarm systems. Integration considerations include maintaining fire ratings around system penetrations and ensuring compatibility between passive and active fire protection strategies.

Advanced Materials and Coatings

Intumescent coatings that expand when exposed to heat provide thin-film fire protection for structural steel members while maintaining architectural appearance. Phase-change materials and advanced ceramics offer enhanced fire resistance performance in specialized applications. Fiber-reinforced materials provide improved structural performance during fire exposure.

Research and Development

Next-Generation Fire Protection

Current research focuses on developing fire protection materials with reduced environmental impact while maintaining or improving fire resistance performance. Nanotechnology applications in fire protection coatings show promise for enhanced performance with reduced thickness requirements. Advanced composite materials offer potential for lighter-weight fire protection systems.

Digital Innovation

Building Information Modeling (BIM) integration is improving the design and documentation of fire-rated assemblies, enabling better coordination between disciplines and more accurate quantity takeoffs. Digital inspection tools and documentation systems are streamlining quality control processes and improving long-term maintenance tracking of fire-rated assemblies.

Publications

-

How to Plan a Chemistry and Art Medals Workshop

Source: 1-Hour Fire Rating Published on 2025-11-21

-

Green Extraction Tree: A Novel Tool to Greenness Metric for Green Extraction of Natural Products

Source: 1-Hour Fire Rating Published on 2025-10-24

-

Hierarchical-Morphology Lignocellulosic Thermostat for High-Efficiency Thermal Management

Source: 1-Hour Fire Rating Published on 2025-09-17

-

Exploring Esketamine’s Therapeutic Role for Perinatal Depression via TASK-1 Tandem Pore Potassium Channels

Source: 1-Hour Fire Rating Published on 2025-07-30

-

Influence of Building Characteristics on Wildfire Smoke Impacts on Indoor Air Quality

Source: 1-Hour Fire Rating Published on 2025-07-10

FAQs

What is the difference between a 1-hour fire rating and other time ratings?

Fire ratings indicate the duration an assembly can withstand standard fire exposure while maintaining structural integrity and preventing flame penetration. A 1-hour rating provides 60 minutes of protection, while 2-hour, 3-hour, and 4-hour ratings provide correspondingly longer protection periods. The choice depends on building code requirements based on occupancy, height, and construction type.

Can I modify a fire-rated assembly in the field?

Fire-rated assemblies must be installed exactly as tested and listed by recognized testing laboratories. Any field modifications require evaluation by a qualified fire protection engineer to ensure the assembly maintains its fire rating. Unauthorized modifications can void the fire rating and create code compliance issues.

How do I know if my assembly has a valid 1-hour fire rating?

Valid fire ratings are documented through listings published by recognized testing laboratories such as UL, Intertek, or FM Approvals. These listings specify exact materials, dimensions, fastening patterns, and installation details required to achieve the rating. Design documents should reference specific tested assembly numbers.

What happens if penetrations are made through fire-rated assemblies?

All penetrations through fire-rated assemblies must be properly sealed with listed firestopping materials and systems that maintain the assembly’s fire rating. The firestopping system must be installed according to manufacturer instructions and applicable building codes. Improper penetration sealing is a common cause of fire rating failure.

How much does achieving a 1-hour fire rating typically cost?

Fire-rated assemblies typically cost 15-25% more than non-rated assemblies, depending on the specific system and application. Additional costs include specialized materials, installation labor, and required inspections. However, fire ratings may reduce insurance premiums and are often required by building codes, making them a necessary investment in building safety.

References

- ASTM International. (2020). ASTM E119-20 Standard Test Methods for Fire Tests of Building Construction and Materials.

- International Code Council. (2021). International Building Code.

- National Fire Protection Association. (2021). NFPA 101: Life Safety Code.

- Underwriters Laboratories. (2023). Fire Resistance Directory Online.

- Underwriters Laboratories. (2019). UL 263: Standard for Fire Tests of Building Construction and Materials.